CopyRight © 2019 Shanghai Wode Mechanical & Electronic Co., Ltd

Hotline:

021-58085802

Address: 21th building, NO. 2666, Xinsiping Rd. , Fengxian Area, Shanghai, China

Mobile:+86-13916890402

Email: Jarl.wang@sh-wode.com

Fax:021-58085802

Our Advantage

Shanghai Wode was founded in 2007 as a specialty CNC precision machining company.

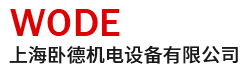

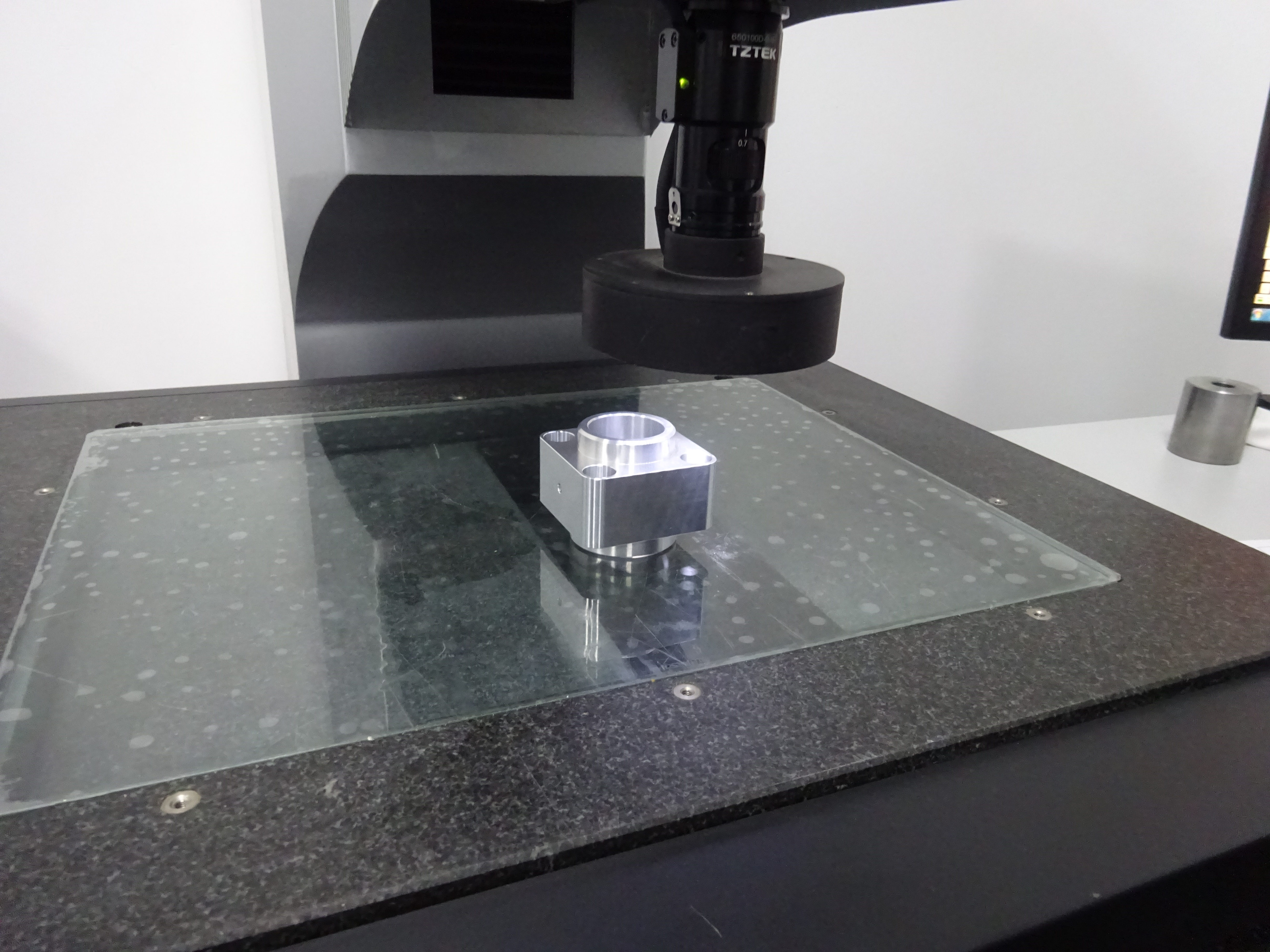

We are proud to offer you perfect quality components through our technology and experience. Over the years, our company has grown into a successful machine shop with more than twenty sets different CNC, CMM, projectors and kinds of measuring equipment throughout a 1500 m² facility. We specialize in steel CNC machining, but are also more than capable of working with iron, aluminum, copper and plastic. Especially in small batch and multi-species orders. The products involve high-end fields such as industrial digital printing, medical treatment, semiconductor, UAV base station, nuclear power and so on. The combination of these key attributes results in exceptional performance and customer satisfaction.

We believe Cooperation Through Reliance.

Product Display

Provide precision machining and assembly.

Equipment Processing

Provide high precision machinery parts processing, production and assembly.

CNC machini

CNC machini

Four axis machining

Customer atisfaction is our greater pursuit

Provide high precision machinery parts processing, production and assembly.

Rich processing experience, mature service concept

Raw Material Purchasing→Raw Material Cutting→Rough Machining→Heat Treatment→Final Machining→FA Checking→buffering→Finishing→Marking→Packing→Delivery

News

Provide high precision machinery parts processing, production and assembly.